Introduction: Revolutionizing Aluminum Extrusion with Innovation

The aluminum extrusion process has undergone significant advancements over the years, with innovations focused on enhancing precision, efficiency, and sustainability. Surat Aluminium is at the forefront of this transformation, adopting advanced extrusion techniques to meet the evolving needs of industries worldwide. From cutting-edge machinery to bespoke solutions, Surat Aluminium has established itself as a leader in delivering superior aluminum profiles for a variety of applications.

In this blog, we will explore the advanced aluminum extrusion techniques employed by Surat Aluminium and how they are revolutionizing the manufacturing landscape.

Understanding Aluminum Extrusion: A Brief Overview

Aluminum extrusion involves shaping aluminum into specific profiles by forcing it through a die. The process allows for the creation of lightweight, durable, and versatile profiles used across industries like construction, automotive, aerospace, and renewable energy.

The basic steps in aluminum extrusion include:

- Billet Heating: Aluminum billets are heated to make them malleable.

- Extrusion Process: The heated billet is forced through a die to create the desired shape.

- Cooling and Stretching: The extruded profile is cooled and stretched to achieve the required dimensions.

- Finishing: The profile is cut, treated, and finished according to client specifications.

Surat Aluminium has refined each of these steps through the integration of advanced technologies, resulting in improved product quality and manufacturing efficiency.

Advanced Extrusion Techniques at Surat Aluminium

Surat Aluminium employs a variety of advanced techniques to achieve precision and efficiency in its extrusion processes. These techniques not only enhance product quality but also reduce waste and optimize energy consumption.

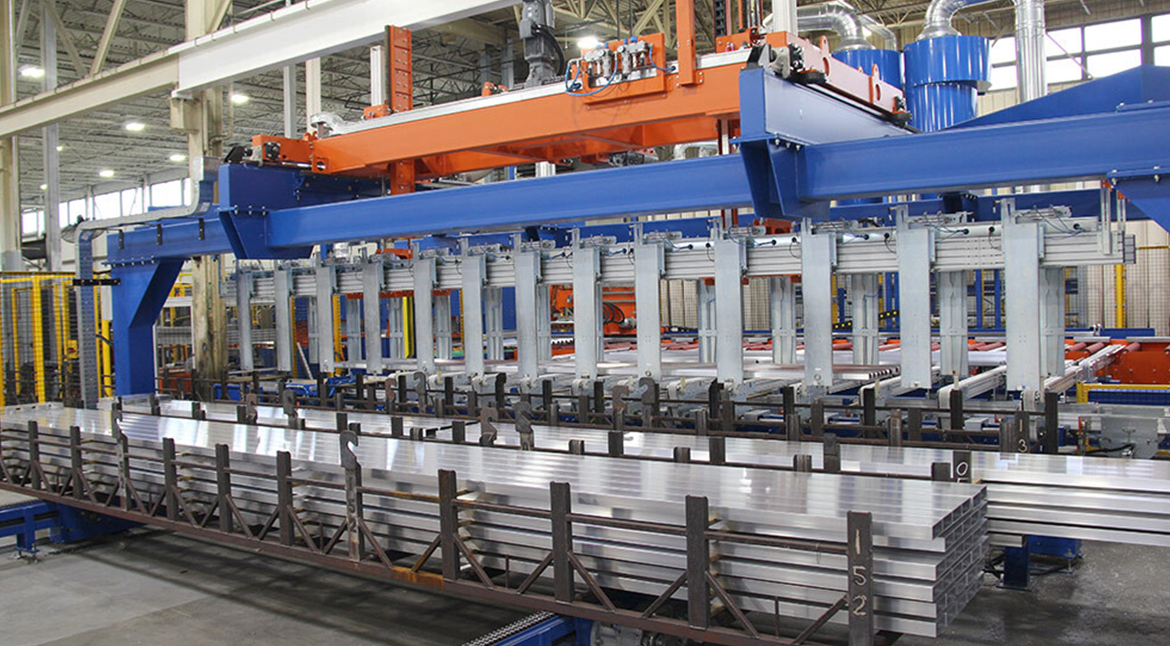

1. High-Capacity Extrusion Presses

One of Surat Aluminium’s key strengths is its use of high-capacity extrusion presses ranging from 10 MN to 30 MN. These presses enable the production of both solid and hollow profiles with exceptional accuracy.

Benefits:

- Ability to produce profiles up to 450mm in width.

- Enhanced precision with tolerance levels as low as 1.3mm for solid profiles and 1mm for hollow profiles.

- Capability to handle complex designs and large-scale production.

2. Multi-Step Heat Treatment Process

Heat treatment is crucial in improving the strength and durability of aluminum profiles. Surat Aluminium utilizes a multi-step heat treatment process that ensures uniform hardness and improved mechanical properties.

Key Techniques:

- Aging: Enhances the strength of the profile by altering its microstructure.

- Quenching: Rapid cooling to lock in desired properties.

- Annealing: Softens the aluminum for further processing.

3. Precision Cutting and Machining

Surat Aluminium employs advanced cutting and machining techniques to deliver profiles with millimeter-level accuracy. This precision reduces downstream processing and ensures seamless integration into client projects.

Tools and Technologies:

- CNC machines for precise cutting and shaping.

- Automated saws for uniformity in cut lengths.

- Custom jigs and fixtures to handle complex profiles.

4. Surface Finishing Techniques

Surface finishing is an essential part of the extrusion process, enhancing both the aesthetics and performance of aluminum profiles. Surat Aluminium offers a range of finishing options, including anodizing, powder coating, and mechanical polishing.

Popular Finishing Techniques:

- Anodizing: Provides corrosion resistance and a smooth surface finish.

- Powder Coating: Adds a protective layer and enhances appearance.

- Mechanical Polishing: Improves surface texture and prepares the profile for further treatment.

Advanced Die Design and Manufacturing

The die is a critical component in the extrusion process, determining the shape and accuracy of the final profile. Surat Aluminium invests heavily in advanced die design and manufacturing to ensure optimal performance and longevity.

Die Design Process:

- Conceptual Design: Understanding client requirements and creating initial sketches.

- CAD Modeling: Using computer-aided design to create precise 3D models.

- Simulation: Testing the die design using virtual simulations to identify potential issues.

- Manufacturing: Producing the die using high-grade materials and advanced machining tools.

Sustainability in Advanced Extrusion Techniques

Surat Aluminium is committed to sustainability and integrates eco-friendly practices into its advanced extrusion techniques. These efforts align with global sustainability goals and reduce the environmental impact of manufacturing.

Eco-Friendly Practices:

- Energy-Efficient Equipment: Utilizing machinery that reduces energy consumption.

- Recycling Initiatives: Maximizing the use of recycled aluminum billets.

- Waste Reduction: Implementing processes to minimize waste during production.

By adopting sustainable practices, Surat Aluminium not only contributes to environmental conservation but also meets the growing demand for green manufacturing solutions.

Applications of Advanced Aluminum Profiles

The advanced extrusion techniques employed by Surat Aluminium allow for the production of custom profiles for various industries. These profiles offer superior performance and reliability in critical applications.

Key Industries Served:

- Aerospace: Lightweight profiles for aircraft structures.

- Automotive: Durable components for vehicle frames and body panels.

- Construction: Structural profiles for windows, doors, and facades.

- Renewable Energy: Frames for solar panels and wind turbines.

- Industrial Machinery: Components for heavy equipment and machinery.

Future Trends in Aluminum Extrusion

The aluminum extrusion industry continues to evolve, with new technologies and trends shaping its future. Surat Aluminium stays ahead of these trends by investing in research and development and adopting innovative solutions.

Emerging Trends:

- 3D Printing with Aluminum: Combining extrusion with additive manufacturing.

- Smart Manufacturing: Utilizing IoT and AI to optimize production.

- Lightweight Alloys: Developing new alloys with improved strength-to-weight ratios.

By staying ahead of these trends, Surat Aluminium ensures its clients receive the most advanced aluminum extrusion solutions available.

Conclusion: Driving Innovation in Aluminum Extrusion

Surat Aluminium’s commitment to innovation, precision, and sustainability has made it a leader in the aluminum extrusion industry. By employing advanced extrusion techniques, the company delivers high-quality, custom profiles that meet the stringent requirements of various industries. With a focus on continuous improvement and customer satisfaction, Surat Aluminium is shaping the future of aluminum manufacturing, providing solutions that are both innovative and eco-friendly.