Introduction: The Role of Precision Cutting in Aluminium Manufacturing

In aluminium manufacturing, precision cutting solutions play a critical role in ensuring accuracy, consistency, and efficiency. The ability to achieve millimeter-level accuracy in cutting aluminium profiles is essential for delivering high-performance products that meet client specifications. Precision cutting not only enhances product quality but also reduces material waste, production costs, and lead times.

At Surat Aluminium, we leverage advanced cutting technologies to deliver custom aluminium profiles that meet global standards. Our state-of-the-art precision cutting solutions ensure that clients receive dimensionally accurate profiles that fit seamlessly into their applications.

This blog explores the importance of precision cutting in aluminium manufacturing, the technologies used, and how Surat Aluminium enhances efficiency through cutting-edge solutions.

Why Precision Cutting Is Essential in Aluminium Manufacturing

Precision cutting is a critical process in aluminium manufacturing that ensures profiles meet exact specifications. Achieving tight tolerances in cutting is essential for ensuring that aluminium profiles fit perfectly into client applications.

Key Benefits of Precision Cutting:

- Dimensional Accuracy: Ensures that profiles meet design specifications with millimeter-level precision.

- Reduced Material Waste: Minimizes waste generated during the cutting process.

- Enhanced Product Quality: Improves the fit and functionality of aluminium profiles.

- Cost Efficiency: Reduces production costs by optimizing material usage.

- Time Savings: Speeds up the manufacturing process, reducing lead times.

By investing in precision cutting technologies, manufacturers can achieve higher efficiency and improved product quality.

Advanced Cutting Technologies at Surat Aluminium

At Surat Aluminium, we use advanced cutting technologies to ensure precision and consistency in our aluminium profiles. Our cutting solutions are designed to meet the specific needs of various industries, including automotive, construction, aerospace, renewable energy, and industrial machinery.

1. CNC Cutting Machines

We use CNC (Computer Numerical Control) cutting machines to achieve high-precision cutting with millimeter-level accuracy.

Key Features:

- Automated Controls: Ensures consistent cutting across large production runs.

- High Precision: Achieves tight tolerances and accurate dimensions.

- Versatility: Can handle complex shapes and custom profiles.

Benefits:

- Improved Accuracy: Reduces dimensional variations.

- Reduced Waste: Minimizes material waste during cutting.

- Enhanced Efficiency: Speeds up the production process.

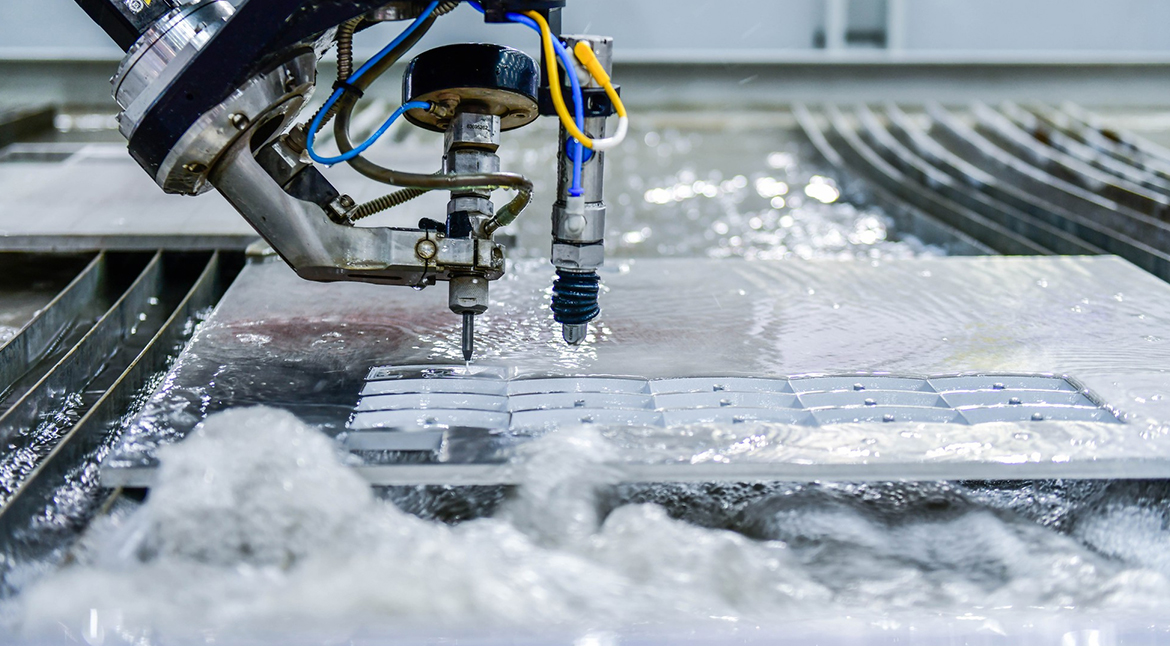

2. Automated Saws

We use automated saws to achieve uniform cuts across large batches of profiles.

Key Features:

- Precision Blades: Ensures clean and accurate cuts.

- Automated Controls: Reduces human error.

- High Throughput: Handles large-volume orders efficiently.

Benefits:

- Consistency: Ensures that all profiles meet dimensional specifications.

- Speed: Speeds up the cutting process, reducing lead times.

- Cost Savings: Reduces labor costs by automating the cutting process.

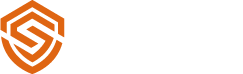

3. Waterjet Cutting

For complex shapes and intricate designs, we use waterjet cutting technology, which uses a high-pressure stream of water to cut through aluminum profiles.

Key Features:

- High Precision: Achieves tight tolerances.

- Versatility: Can cut complex shapes and patterns.

- No Heat: Prevents thermal distortion of the material.

Benefits:

- Enhanced Quality: Ensures smooth edges and accurate cuts.

- Material Preservation: Reduces the risk of material damage.

- Flexibility: Suitable for custom designs and complex profiles.

Industry Applications of Precision Cutting Solutions

Precision cutting solutions are essential in various industries to ensure that aluminium profiles meet specific requirements.

1. Automotive Industry

In the automotive sector, precision cutting ensures that aluminium components fit perfectly into vehicle assemblies.

Key Products:

- Chassis Components

- Battery Enclosures

- Crash Management Systems

2. Construction Industry

In construction, precision cutting ensures that aluminium profiles meet the dimensional requirements of building facades, roofing systems, and structural components.

Key Products:

- Curtain Wall Systems

- Window and Door Frames

- Roofing and Cladding Panels

3. Aerospace Industry

In the aerospace industry, precision cutting ensures that aluminium components meet tight tolerances to ensure safety and performance.

Key Products:

- Aircraft Fuselage Sections

- Wings and Tail Sections

- Engine Components

4. Renewable Energy Sector

In the renewable energy sector, precision cutting ensures that aluminium profiles fit perfectly into solar panel frames, wind turbine components, and energy storage systems.

Key Products:

- Solar Panel Frames

- Wind Turbine Components

- Battery Enclosures

5. Industrial Machinery

In industrial machinery, precision cutting ensures that aluminium profiles meet the dimensional requirements of machine frameworks, protective enclosures, and cooling systems.

Key Products:

- Machine Frames

- Protective Enclosures

- Cooling Fins and Heat Sinks

How Surat Aluminium Ensures Precision and Efficiency

At Surat Aluminium, we have implemented strict quality control measures to ensure that our precision cutting solutions meet global standards.

Key Quality Control Measures:

- Dimensional Inspection: Using precision measuring tools to verify that profiles meet specified dimensions.

- Surface Inspection: Ensuring that profiles have a smooth and defect-free surface finish.

- Mechanical Testing: Verifying the strength and performance of aluminium profiles.

Our quality control processes ensure that clients receive high-quality products that meet their specific requirements.

The Benefits of Precision Cutting for Clients

Precision cutting solutions offer numerous benefits for clients across various industries.

Key Benefits:

- Improved Product Fit: Ensures that aluminium profiles fit perfectly into client applications.

- Enhanced Product Quality: Achieves smooth edges and accurate cuts.

- Reduced Material Waste: Minimizes waste generated during the cutting process.

- Cost Savings: Reduces production costs by optimizing material usage.

- Time Savings: Speeds up the manufacturing process, reducing lead times.

Conclusion: Partnering with Surat Aluminium for Precision Cutting Solutions

Precision cutting solutions are essential for enhancing efficiency and ensuring product quality in aluminium manufacturing. At Surat Aluminium, we leverage advanced cutting technologies to deliver dimensionally accurate profiles that meet the specific needs of various industries.

By investing in cutting-edge cutting solutions, we ensure that our clients receive high-performance aluminium profiles that drive efficiency, performance, and sustainability.

Partnering with Surat Aluminium means gaining access to precision cutting solutions that help you achieve operational excellence and sustainable growth.